Hi Everyone!

We just released software version 0.6.2. We're incredibly excited about these features and wanted to let you know all about them

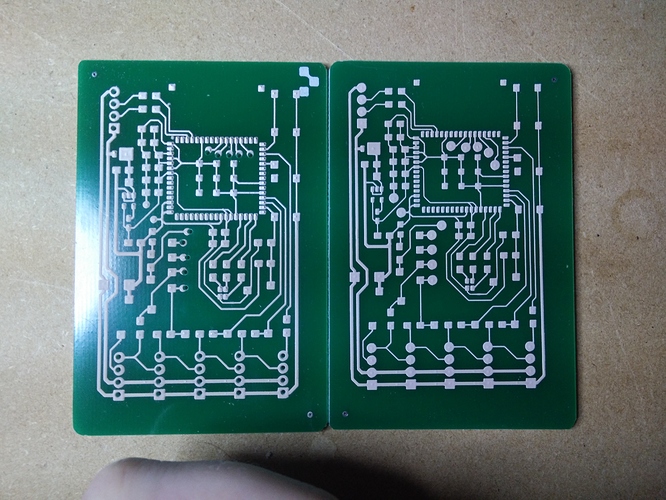

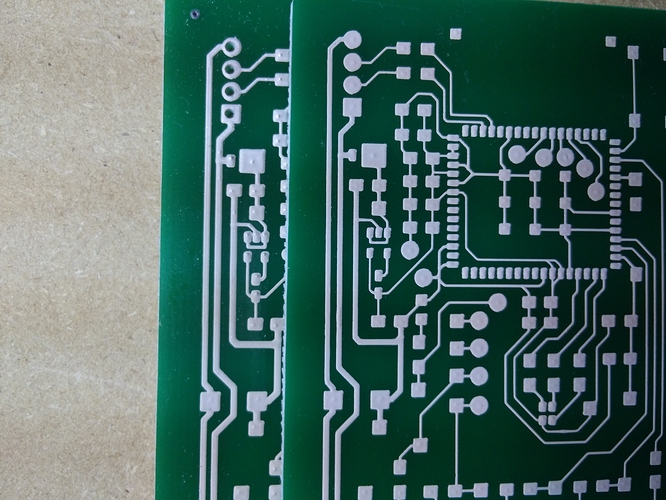

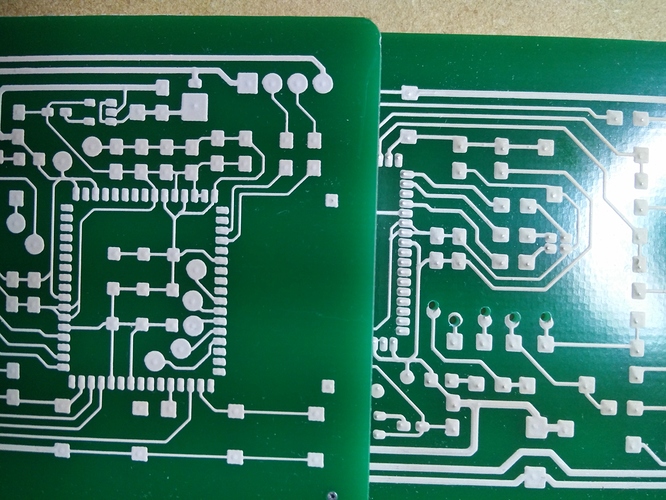

Double Sided Printing

Finally, it's here! (@emcniece, @lintilla, @DavidYon47)

The next time you print a circuit, you will have to choose between a simple or an aligned print.

A simple print will let you position the circuit wherever you want. You will be able to click and drag the circuit around to place it somewhere on the substrate. (This was the standard behaviour before v0.6.0)

An aligned print will let you position the circuit by identifying two key features on the board. Just like in solder paste dispensing, the location of two points needs to be measured using the arrow keys.

Important: For alignment purposes, the software will pick the two smallest pads that are farthest apart. It gives priority to pads with holes (thru holes or vias), followed by regular pads (SMT pads), followed by traces.

A double sided circuit consists of two separate prints: A simple print followed by an aligned print. During an aligned print you will have to locate the position of two holes. A user guide on double sided printing will be posted here22.

Faster Printing

Over the past few weeks we've been experimenting with faster printing speeds. We realized we could increase the printing speed by 66% without any negative effects.

A Hello World circuit now takes 3 minutes and 22 seconds to print! The software will automatically start using the faster print speed once it updates.

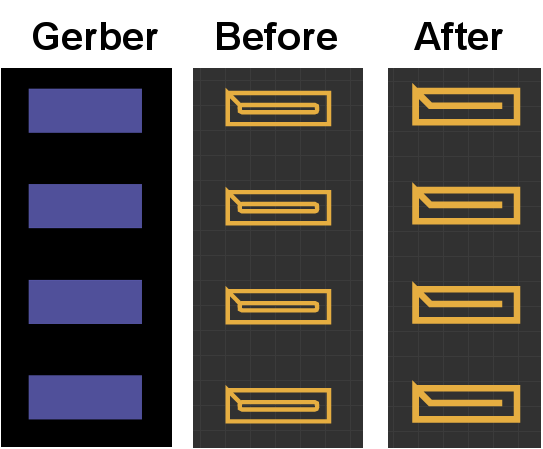

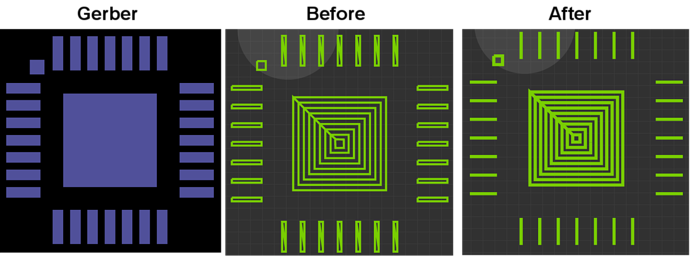

Less ink in pads

Several of you have noticed the 'dimples' that are left behind at the center of the pads when the nozzle raises. It is hard to eliminate them altogether, but they tend to be exaggerated when too much ink is dispensed in one area. We have modified the software so that the innermost pass of the pad can now be a line instead of forcing it to be a rectangle. This will reduce over-filling and should lead to more uniform pads. (@Don)

Fun fact: Here at Voltera HQ we call the 'dimple' a 'kiss'. (like a Hershey Kiss)

Similarly, very small thin pads will now be drawn as a single line, instead of a rectangle, this will help reduce the risk of shorting if you are printing fine pitch ICs.

Other

- We have added Alt+C as a shortcut to bring up the console. This shortcut is more accessible in international keyboards and is more in line with the other shortcuts (like Alt + R, Alt + H). Thanks @Eriond for the tip!

- Release notes have been added to the app, when the app is updated they will be displayed automatically so you can stay in the loop.

- Previously, if you had rectangular pads with rounded corners the software would not be able to process them and would render a circle instead. We've patched the issue now.

That is it for now, but if you have general feedback, questions or feature requests, please comment below.

Cheers,

Jesus Zozaya

created

last reply

- 14

replies

- 5.5k

views

- 4

users

- 8

likes

- 7

links

.

.