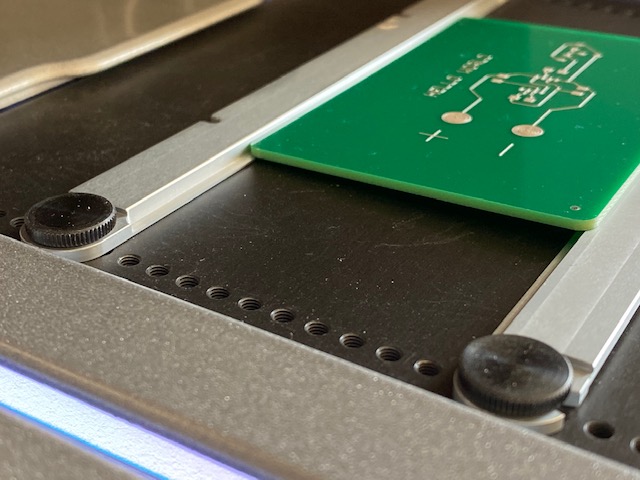

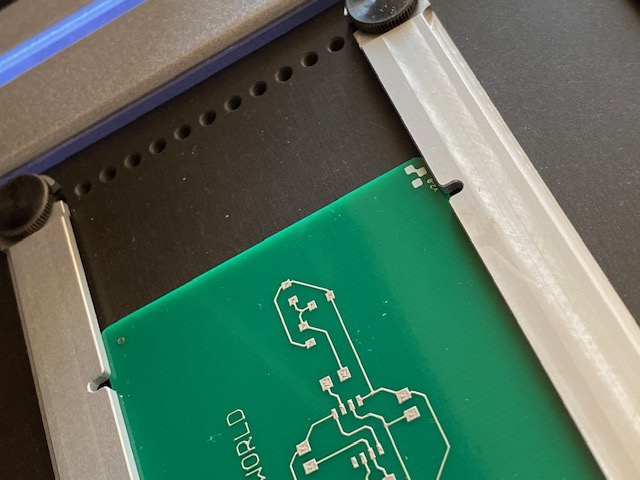

When going from ink to heat, and then from heat to solder paste, I always have to completely remove one clamp and its thumbscrews, shift it away from the other clamp by one hole, and then re-secure it before the stock 2"x3" substrate will fit.

For example, if I position the clamps so that the PCB is securely held in the clamp and then swap the clamps (as shown in the embedded video), the PCB is just slightly too large and won’t rest on the inner baking cutout.

If I start from a position where the PCB rests securely between the clamps on the baking cutout, then when I flip the clamps around, the PCB is only held on by a fraction of a mm.

Can anyone please tell me what I’m doing wrong here?