Outlining an aligned print when you are not aligning on features lets you see where the art is going to print on your board as a whole. See the gerber file that got submitted by me in the support package tonight when the printer broke my last needle  The board has traces and pads that are lower/higher on the y axis than the pads it is using to align on, which are the 0603 cap pads in the top left and bottom right. I'm trying to print it on 2x3 substrate aligned with the 3" side along the Y axes (Matt has a photo of the setup in the backlash support ticket).

The board has traces and pads that are lower/higher on the y axis than the pads it is using to align on, which are the 0603 cap pads in the top left and bottom right. I'm trying to print it on 2x3 substrate aligned with the 3" side along the Y axes (Matt has a photo of the setup in the backlash support ticket).

I'm working on a friends laser at the moment, and I'm thinking what I really want is something entirely different to the current setup procedures. What I'd really like for the boards i'm setting up is to instead of moving the artwork around the bed in the software, be able to set a user definable origin. On pretty much every laser cutter i've worked with (Epilog, Trotec, Ruida, Light Object) I can move the laser head to where I want it, and tell the laser to cut the art work with that point as the top left, right, bottom left, right, or centre. The art's bounding box is then snapped to that point (in Trotec's software you can see the current head position and snap your work to that point on any of the corners). On a Haas VMC I'd be setting up the job fixture on the bed, and then tell the machine the job offset from home - or use a touch probe to go find it more precisely. I don't need to move my job around in the CAM software, it understands fixturing. Mach3 does this too, but is a bit more annoying to do it with. Anyway, the laser cutters all do this brilliantly from a functionality point of view if not from a GUI point of view.

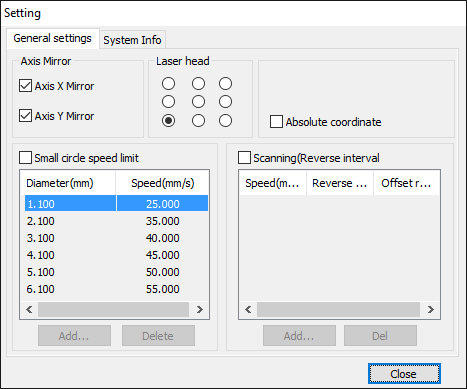

Since I have Ruida's software open now:

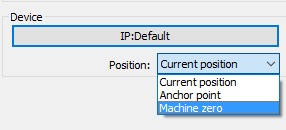

So now my origin will be in the bottom left of my bounding box ("Laser head" group box), I can either tell the machine to use "current position" or "home position" for that reference point. Home will start from where it homed to, and "current position" uses the current laser head position as 0.

So now I load the first DXF I come across on my PC:

You can see the machine's home is top right, and the green box is where the laser is going to cut from. The position of the art on the bed is irrelevant because:

Position is set to Current position, meaning it will run the cut from the head position. I can also fixture places on the machine or just go from home (which it would refuse to do, as I have the head position set to bottom left, the artwork would be going into negative units positions out past home).

Currently, V-One software allows me to position the art on the bed, and repeatedly move it trying to get it into the right place. I want to move the head of the machine, tell it where to start from one corner of my art, and have it go from there. So if I want to print my art on the bottom (relative to Y) of my substrate, just above the clamp bar, I can position the machine's probe to that point, and then tell it that it's going to work from the bottom left (or right). If i want the print dead centre in the middle of a bit of substrate, I can put a dot with a sharpie in the middle of the material, and line the probe up with that, then off I go printing. If I'm trying to get an SMA connector right on the top right edge of the board I can set my origin to the top right of the bounding box, and then move the probe to just below the clamp bar and just onto the right side of the board and hit go.

Hopefully that makes some sort of sense!