Hi everybody,

We want to bring up a big oversight in the new V-One Drill attachment.

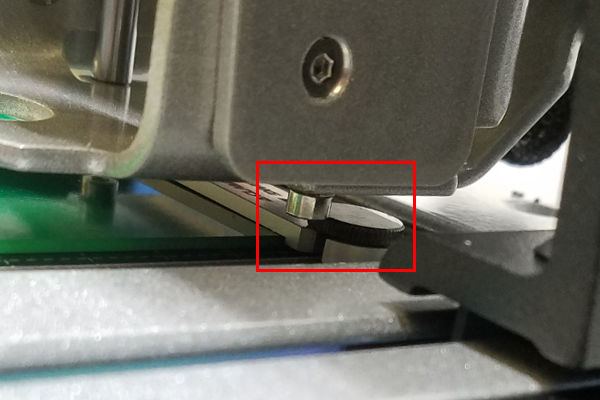

When the sacrificial layer is mounted and a board is clamped, the thumbscrews sit about 1.0mm taller. Tall enough to make contact with one of the screw heads on the bottom of the carriage.

.

.

What does this mean?

If you are drilling or printing large boards there is a potential for the carriage to hit and stall, it may not happen every time as it depends on the path the carriage takes. The motors will make an odd noise and your positioning will be off. You will be unable to drill or print in this area properly.

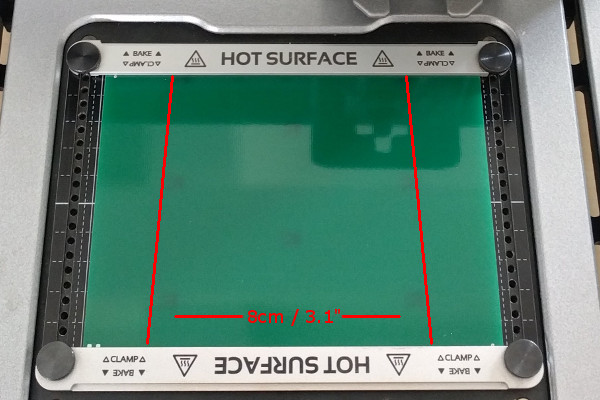

This interference reduces the effective printing area to 8 cm x 10.4 cm / 3.1" x 4.1" shown below (approximately):

Short term solutions

- If you can, position your circuits in the center of the bed and rotate them 90 degrees so they avoid the edges altogether.

- For the time being, stick with 3" x 4" or 2" x 3" circuits. This issue only pop ups when using our largest board (4" x 5")

- The interference is about 0.5mm or less, if you need a solution today and have access to a file or sander you can shave down the thumbscrews.

Long term solution

We are going to be modifying our clamps so that the thumbscrews sit a little bit closer to the bed. This will provide enough clearance and fix the problem.

It will probably take about 2-4 weeks to get the clamps, but when they are ready we’ll be sending a pair to everyone that has purchased a new drill attachment.

We will contact drill owners with the tracking number in a few weeks.

How did we miss this?

Good question. We are a bit perplexed how something so obvious was missed during development. Most of our testing was done with boards smaller than 3" x 4", so I guess there’s a lesson to be learned here.

Regardless - we want to apologize to our community and make things right.

Jesus Zozaya