@a2retro We've tested flex circuits in the past, and have had decent results! To test the ink performance, we first prepared a number of samples consisting of a conductive ink traces on Kapton substrates of different thicknesses (see below).

We then ran a series of tests to determine:

The permanent change in trace resistance after repeated flexing

The permanent change in trace resistance after flexing the substrates at increasingly aggressive bend radii

The transient change in trace resistance while flexing the substrate

Maximum bend radius before failure

Despite the fact that the ink is not optimized for flexibility, we found that it performed quite well as a flex conductor.

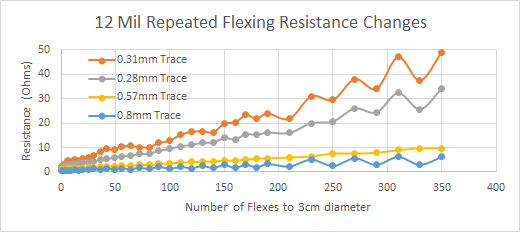

The chart below shows a test we ran on 12-mil thick Kapton, flexing a set of traces of different widths repeatedly at a fixed bend radius:

The resistance of the trace will steadily increase with repeated flexing, though wider traces are not affected as much. The resistance of the traces will also increase while they are flexed, with larger changes at more aggressive bend radii.

At aggressive bend radii (around 1mm) the ink does tend to fracture, but will hold up well for mild flexing. For this test, we used a simple setup consisting a DMM and a camera, measuring both the bend radius and the trace resistance while flexing the samples (see below)

Based on our results, the conductive ink is more suitable for static flex applications (where the conductor is flexed at a fixed bend radius for extended periods) rather than dynamic flex (where the ink is repeatedly flexing). For more aggressive flexing, I would recommend using wider traces to minimize the chance of fracture and to maintain a more consistent trace resistance.