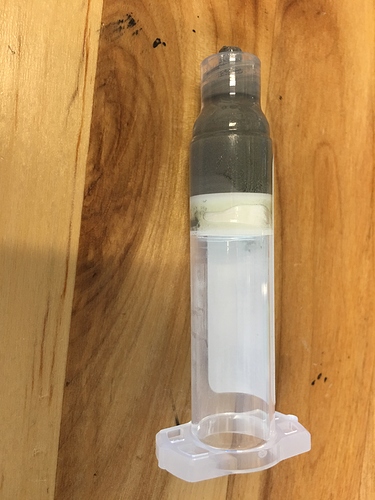

I’m actually using T5 paste now… There was no change from using T3. I know the nozzle being longer will require more pressure, but that is not the problem anyway… I have gone through two packs of original nozzles so far as well. it is one reason I was looking for a alternative nozzle as it was starting to cost a lot to keep replacing them.

I did not know there was a difference between the red and white… But I think in all my previous tests I probably had randomly chosen one or the other anyway. I don’t think it would really make any difference. The problem is the metal plunger being tapered along with the red or white piston is just inherently going to have the metal plunger increase the diameter of the red or white piston. There is no way the smaller Voltera nozzles would work either. As they would require a little bit more pressure, and it would just jam up just the same as it is doing now anyway.

If you go back to my video I posted, the paste comes out incredibly easy initially… I really just turned the pressure down and wait for it to stop leaking, then when I start printing, after several pads it just simply stops dead, if I remove the cartridge and turn the gear manually even like 50 times, the paste just refuses to come out. With such an incredible amount of pressure on it there is just no way the nozzles can block up to that extent.

I had kept blaming the paste and the nozzles for the past few weeks… I have swapped and changed both of them for various brands of paste and nozzle sizes and there is just no way to print more than several pads before the whole thing Jams up again… Unless of course I use a lot wider diameter nozzle in which case it will continue printing fine.

But adding the nut in as on the forum link I posted has solved this problem. I printed a couple days ago and it was fine, I just left the cartridge in the printer for another couple of days, printed again, and it is still working fine. So just for whatever reason, the syringe pistons and the Voltera metal piston are just simply not a good match for each other.